Upstaged

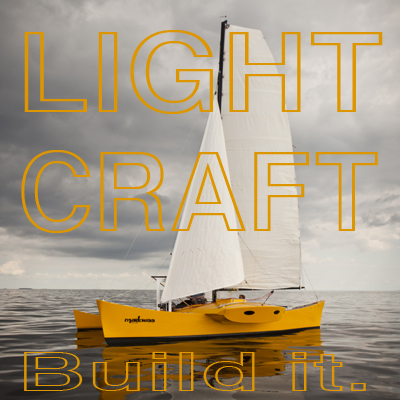

Multihull designer Bernd Kohler has thus far been solely devoted to catamarans, but his latest design is for a simple small trimaran, logically named LITTLE TRI. I like Bernd’s work because he places simplicity of build and economy high on the list of design priorities, and yet still manages to come up with appealing boats. His latest is a classic example, where he sidesteps the usual trimaran complexities by employing a readily available local industrial product for the outriggers, instead of building up the amas from scratch out of plywood. It’s much the same approach that SE Asia takes with their outrigger canoes, building the amas from readily available bamboo, and Bernd does make the point that LITTLE TRI is closer to that model than the modern, high buoyancy ama trimaran.

This example is the first LITTLE TRI built by an owner/builder.

Via Small Trimarans.

I bought these plans, but having a little trouble getting the Oakume and aluminum tubing . they all want to cut it in shorter pieces to ship to me or I can’t buy the plywood because the shipping is as high as the wood it’s self. I will keep on gathering, just may take me longer. . I may make me some laminated birds mouth arms until I find the aluminum. I just don’t want to get too far away from Mr. Bernd Kohler’s great design