Sgian Ghlas - the Cold Water Proa

SGIAN GHLAS (Grey Knife in Gaelic) is a new 24’ foam cored fiberglass proa submitted by Topher Dawson of Ullapool Scotland.

At first glance I thought it was the second silliest proa design I’d ever seen! Like someone had accidentally beached their dory on the back of a small submarine or a Narwhal? However, Topher Dawson is perfectly serious about his new proa, and as I studied the odd craft and read his reasoning for it, I found myself nodding along. Mr. Dawson’s take on the “western” Pacific proa is original, creative and thought provoking. I hope you enjoy hearing about it as much as I did. -Editor

24ft Proa Design Considerations

By Topher Dawson

Proas have always fascinated me, because they represent a completely separate concept of how to make a sailing boat from anything we have in the west. Readers of this site will know what a proa is, but I want to examine the design choices open to us.

The Micronesian proa is a long, thin, fairly heavy canoe made from a dugout log with or without additional planks or strakes. It gets its stability from the weight of a single outrigged log or hull which is flexibly mounted to windward. The rig is fairly small by western racing standards, and the craft gets its speed from being very easily driven. The load is carried in the main hull although crew sometimes hike out to windward. The stresses in the connecting structure are fairly low, and can be taken by the timber and natural fibre lashings.

A western designer is likely to depart from this concept but needs to know why. Some designers have perhaps gone too far and in the process lost some of the best features of the proa. I will refer back to the traditional proa later.

After many years and proa models I decided to really make one, and settled on the biggest proa daysailor I could reasonably load on a trailer.

Using polyester roofing resin for cheapness and urethane foam as a core has turned out a pretty light (250kg without ballast or crew) and a very strong and stiff boat. The proa concept works without getting manic about lightness.

To get the trailing length down to about 18ft I made the noses come off. They stow within the middle part of the hull and are fairly easy to lift. They bolt on with 4 x10mm stainless bolts embedded in the nose bulkhead which come through holes in the middle hull section bulkhead.

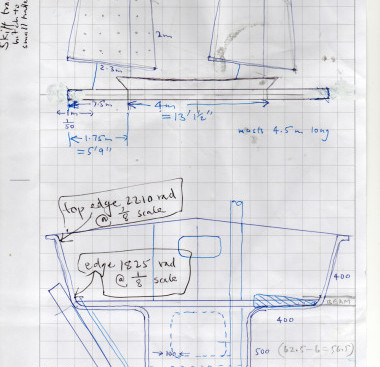

The main hull is 24ft long and 2ft wide at the waterline, so 12:1 length to beam. At this narrow ratio it does not seem to matter much what the cross section is, so I opted for a flat bottom and vertical sides with heavily radiused chines. Rob Denney’s Harryproas do this and don’t seem to suffer. It allows the bottom to be heavily made on its bottom surface, to withstand the ground, and the top surface, to make a durable floor without extra structure. As with Harryproas there is nearly no rocker, just about 80mm in the last meter of the ends.

Proa crews in Micronesia sit in the main hull bailing furiously or on the deck structure. This may be OK in Micronesia but not here in Scotland where hypothermia would set in fairly quickly. I’ve also found a flat deck multihull pretty uncomfortable as I’ve never mastered squatting.

So the plan needed a comfortable and sheltered place for sitting. Using the center section of the canoe hull as a foot well, I drew a flat seat extending outwards and sloping slightly downwards from the top of the hull side, and then a sloping seat back rising up. Extended to the ends of the cockpit this forms a double ended dory type hull with a forwards flaring “bow” at each end. It looks nice, throws the spray outwards, and keeps me warm and sheltered.

Submarines steaming along on the surface have their noses under water with a transition to dry decks about a third of the way aft. I figured I did not mind the noses, which are sealed boxes, having water over their decks sometimes, as long as the cockpit remained dry.

Proas tend to have a nose down attitude due to the rig thrust being high up. In this boat the crew weight aft will help but I wanted a lot of spare buoyancy in the noses to prevent nose dives. They displace about 450 kg each fully immersed, which is about the loaded displacement of the whole boat. Empty, the proa floats with about 100mm draft in the main hull, and if the 100kg ballast water is in the outrigger it draws about 125mm. When laden with two crew the main hull draws about 150mm but could carry a lot more.

I did not want torsion forces in the deck beams so they meet at a point above the outrigger. They meet the open center section of the boat at its end bulkheads so in fact they protect it against torsion.

A GRP bracket is bolted to the outrigger junction which has two strong cheeks going down into pockets inside the hull skins of the outrigger. This area of the outrigger hull is heavily reinforced with bulkheads and glass. There is a 50mm diameter heavy wall stainless tube axle which passes through hull sides and cheeks, allowing the hull to pitch freely. If this starts to scare me by trying to nose dive in waves I will add soft rubber blocks as limit stops. Effectively this is what traditional proas achieve with bendy ends to deck beams.

So far it has worked well, with the float hull conforming well to waves without jarring the rest of the boat.

The masts, deck beams and rudder shaft are all aluminum scaffold tubes, 48.3mm diameter, 4.47mm wall. They are of an alloy which rests salt water and is forgiving of surface abrasion unlike thinner wall tube.

The masts cannot on their own withstand the bending moment needed to lift the outrigger with 100kg of water, so there are single Dyneema stays to windward for each mast.

The rig is simple, small and low, being two identical lug sails of 100 sq ft each, recut from a single heavy mainsail. They each have two sheets, one to a block at the end of the nose and one to a block amidships. Each has a two part tackle, so there is a lot of loose rope in the boat. They set well as long as the luff is sufficiently tensioned.

The rudders are a complex issue as many proa builders have discovered. Traditionally, proas are steered by a helmsman with a large bladed steering paddle. He (I have never seen a picture of a woman steering a sailing proa) sits right aft and jams the shaft of the paddle against the lee side of the hull. Thus he can generate the force needed to counter the weather helm. He is in a welter of spray which is not really practical in Scotland.

There seem to me to be three rudder choices available. One is to mount the rudders as trim tabs on the aft edge of a daggerboard in a case, like Brown and Newick. This does work but the idea of bashing the leading board at speed on a rock with its vulnerable rudder blade, or jamming the aft one in its case or breaking the case, worries me. Another is to use two rudders in the water all the time like Harryproas. This either means rotating both rudders 180 degrees at each shunt, or accepting that leading and trailing edges will swap and working out how to stop the leading rudder flipping over as its axis will be aft of the center of pressure. The third is to do what the Micronesians do and raise the rudder out of the water at one end, and lower a rudder at the other end. This gets the leading rudder out of danger and allows the rudder design to be optimized for one way flow. I also made the choice to keep all the foils outside the hull, so there are no cases to leak or break. All three foils can be retracted above the level of the hull bottom so the boat can sit flat on a beach. All three foils kick up without damage if they strike an object.

In this boat the rudders are large cored glass/foam blades laminated on to aluminum tube shafts. The rudder section is asymmetric with a flat surface on the leeward side and balanced with about 25% of the area forward of the shaft centerline. In this way they can develop a windward force without too much tiller load.

Every time we shunt, one rudder has to come up and the other has to go down. The shafts enter the cockpit through a hole at seat level. When deployed they are at 45 degrees to the vertical, with the top ends passing through the tiller and extending up another foot or so. This end is then lashed aft to keep the bottom end pulled forward into a GRP hook at the waterline. The hook holds a plastic bush which the shaft turns in, with another bush at deck level.

When raised, a lanyard attached to the aft top corner of the blade hoists the blade up and forwards, till the shaft lies along the seat edge and the blade is stowed close to the cockpit nose.

The design choices for proa leeway prevention are either use the hull shape like the traditional proa, use two foils, I.e. two rudders or dagger boards containing rudders, or three foils i.e. two rudders and a centerboard or leeboard.

I don’t want the hull to be developing lift to windward, as it would be an inefficient foil. Ideally I would like it to go straight without leeway as this would incur the lowest drag. To do this the leeboard needs to develop enough lift at zero angle of attack. Speer’s P3 section can develop a lift coefficient of about 0.5 at zero AoA but I don’t know what my sharp edged version is managing.

My 1/8 scale model showed that the three foil solution with the forward rudder retracted could be made to work. The leeboard can rotate fore and aft around its bolt 180 degrees, from fully retracted in one direction to fully retracted in the other. It is actuated by two four part purchases hauling on Dyneema lines wrapped around the upper edge of the board, one in each direction. The tackle line is endless and runs inside the cockpit where it can be grabbed at any point.

The leeboard is also inclined with its tip to windward at about 25 degrees. The purpose of this is to make it lose its grip on the water if the angle of heel should ever reach 45 degrees, i.e. halfway to a real capsize. At this point in a capsize the cockpit side would be immersed and buoyant, and there is a chance that the boat could recover or at least give me time to release sheets.

Traditional proas have a weather helm problem. The main hull is shaped to be more convex on the windward side and flatter on the leeward side, thus making a better shape to generate lift to windward. But the center of lateral resistance will be well forward of midships and the only way to keep the weather helm within bounds is to mount the oceanic lateen rig right forward, with the mast tilted forward. This works well but needs a skilled crew to detach the whole rig from the bow and walk it aft to the new bow at every shunt, tipping the mast over at the same time.

To windward the proa can be made to balance for long periods without steering input, but on a reach and downwind the weather helm needs constant force on the steering paddle.

Like most western sailors I draw the line at carrying the rig to and fro, and have opted for two masts fixed at equal distances from midships. As the sail centers of effort must be slightly aft of their mast to weathercock safely, this means the overall rig center of effort must be slightly aft of midships. Model experiments showed that with the leeboard vertical, the boat needed about 5 degrees of rudder to go to windward, and it steered itself. 5 degrees is optimal for a good lift/drag performance and as the blades are pretty balanced the tiller load is light.

Off the wind, the weather helm builds up, but can be balanced out by raking the leeboard aft. The boat seems to be pretty good at self-steering but not on a broad reach or running downwind.

The leeboard gets flow in both directions so it is an approximation to a Speer P3 section but with sharp edges. I accepted early stall in return for not having a draggy blunt trailing edge. Early stall can be experienced in low winds when starting from rest after a shunt. The boat falls away from the wind as the board loses lift. But it fairly soon recovers as the speed increases.

SGIAN GHLAS Specifications

LOA = 7.5m/24ft

Length without bow noses = 5.5m

Length of ama (float) = 3.75m

Main hull WL beam = 600mm/2ft

BOA = 5m

Draft empty main hull = 100mm

Draft main hull with 2 crew = 150mm

Draft empty ama hull (30kg + 20kg crossbeams) = 70mm

Draft loaded ama with 100kg ballast water = 150mm (50% displacement)

Sail Area 18.5 sq m/200 sq ft

Weight (estimated from draft) = 280kg/617lb without ballast or crew

Video

Sgian Ghlas light wind sail

Sgian Ghlas sailing at Toberonochy

Coming up next: Building the Grey Knife

Very cool. As with Michael, at first sight, it is “dory on torpedo,” and WTF?? But your reasoning is sound and I’m thinking you have the driest proa in existence. 😊 Also like your rudder treatment.

In ‘93 I built a 19’ proa which split into two parts at the center, and was held together with 7 bolts. It worked fine and never leaked. I think your method will be successful also.