Argo the Modular Pod Cat

Well here it is late 2021. The world has been in a COVID-19 mess for 18 months, with no real end in sight. Global supply chains are a complete train wreck, and it’s not looking to change anytime soon. Prices of lumber, especially plywood, have skyrocketed, along with most everything else related to boat building. Back in the day, when so many plywood classics were designed and built, good marine plywood was a very reasonably priced boat building material. However, over the decades it has gone down in quality as much as it has gone up in price and the latest price jump got me to thinking… is plywood now so spendy that other building materials are becoming competitive… like fiberglass?

Classic plastic has the magical ability to conform to any shape you could desire, but the Achilles heel is that it needs a mold, which is like building the whole boat all over again. That is why molded fiberglass is a process best suited for mass production. Unless…

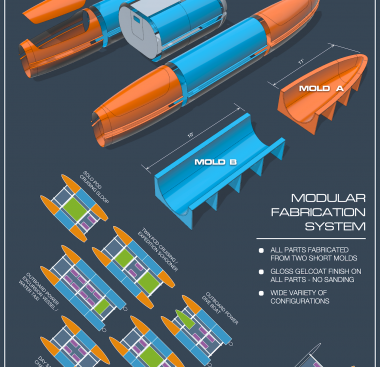

ARGO MOD-FAB

What if we created a simple set of molds that could combine multiple functions, using an optimal design that cuts down on surface area and thickness needed in most areas and could be reinforced locally (crash areas in bow, keels, shroud bases, beam sockets). We know that an elliptical section is the best compromise between ultimate strength and space. Curved surfaces add strength without weight. Think of an egg - all curved, with a thin shell.

Argo is a modular system of fabrication that allows for a wide variety of configurations. The catamaran is made from just two simple molds - each about ten feet in length. Both molds would easily fit inside any garage, or storage unit, or a 20’ container workshop…

The body of the hull is an elliptical tube section, like a Boeing. The bows and sterns are identical, and are also identical top to bottom. You’d make a molded part for the bottom, and make another one, and then turn one over and bond them together at the gunnel. You’d need a half tube mold, and a half bow mold, and that would be it. The pod is made from the same hull molds, plus some extra flats, etc.

You would need 8 bow parts and 4 body parts for the two hulls, plus 3 body parts for the pod. It is mass production on a personal scale, and it makes spending time on the molds worth it. In exchange for the molds, you get a real fiberglass boat, with all the attendant virtues of the material:

- A gelcoat gloss finish w/ virtually no sanding or painting

- Ideal hull sections

- Practically impervious to decay*

- Good resale value

The modular fabrication system encourages a variety of applications: from sail to power, from private adventure yacht to water taxi, fishing boat or charter dive boat.

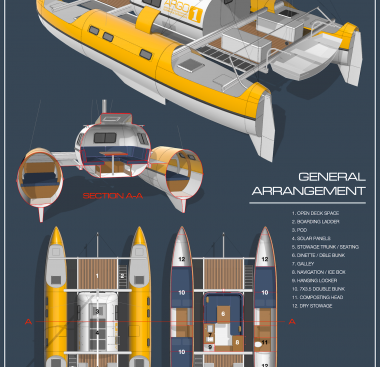

ARGO 1

Argo 1 uses a 5’ high x 4’ wide hull section.She is a 30’ ocean voyager, though she can go longer, up to 40’ if required - just build an extra middle section. She is not designed for top speed, though I think she will be no slouch, especially in the trade winds for which she is meant. She is designed for load carrying because - have you ever seen a small cruising cat that is really out there doing it, that floats on its lines? Me neither. Argo is a capable load hauler.

The catamaran would be built in three large sections - two hulls and central cabin. Her slender hulls with a 9.4:1 L/B ratio are easily driven, allowing a modest sail plan of 440 sq. ft. The sail area to displacement ratio of 20 places the boat slightly above a Cal 40 and well below a Farrier trimaran, but hull flying isn’t really on the agenda.

The central pod houses the galley, eating area, general social space, navigation and solar panel energy systems. The dinette converts into a large double berth. A pop-top provides generous standing headroom. Plenty of storage too.

The hull interiors are kept as simple as possible, with three bunk flats and a composting head compartment. The bunks are 7’ long x 3.5’ wide, which isn’t half bad for a 30’ cat. Fore and aft of the sleeping cabins are generous storage lockers, and fore and aft of those are sealed crash box areas. There are no thru-hulls.

The 5’ of headroom is plenty for sleeping, and the low rounded shape of the roof offers minimal windage and wave resistance. I have cut away the fore and aft sections to make a flat deck to walk on, but that is not strictly necessary for the concept.

Cross beams would all be made from used (oversize) mast sections for low weight, minimal maintenance, and simple construction. The finest place to be on a catamaran is the bridge deck, and Argo 1 has loads of deck space. Decks to fish from, sunbathe, stow a dinghy or crab pots, or maybe just to throw a party. The “walk-around” design of the pod gives excellent access to anywhere on the boat, bow to stern. There is a boarding ramp forward to gain access from the beach or the water. A pair of deck boxes aft provide seating and storage, and I’ve drawn an easily stowed boom tent to set up at anchor.

Argo 1 is a serious cruising catamaran, not a racer, which means sturdy low-aspect ratio keels. No vulnerable daggerboards, no slots taking up cabin space, no moving parts, no worries. Also, no line honors in a race to windward, but gentlemen never sail to windward anyway! I have drawn up two rudder arrangements: one is a high aspect-ratio blade, variable depth, kick-up affair. The other is a short skeg rudder no deeper than the 2.4’ draft keel. The skeg rudders create a four point suspension system with the keels to permit safe and simple beaching. The deep blade rudder is the better performer, until you hit something. At least a catamaran always carries a spare rudder in the other hull.

Another cruising design decision is the rig. You don’t often see gaff-rigged cats these days, however, the gaff is simply a better performer off-wind than the lofty Marconi. The lower center-of-effort reduces heeling and overturning moments, mast height lowers, demands on the shrouds lessen, you don’t need to luff-up to reef or hoist**, and down the design spiral we go. I’m thinking a used sailboard carbon mast might do for the gaff.

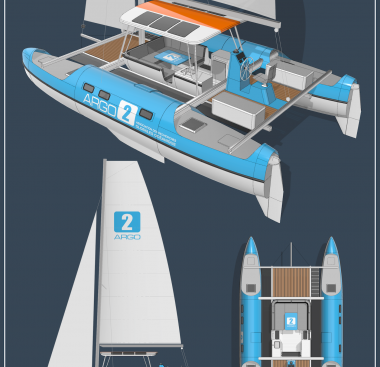

ARGO 2

Argo 2 is a mod of the pod into a resort-style excursion boat - the type tourists rent for a 3 hour tour. The big hardtop provides shade and solar power, while underneath is some seating and refreshments. A clear vinyl and canvas enclosure could make the pod habitable enough even in a rain squall. The raised helm station aft gives the captain a commanding view. The outboard lives directly beneath the helm station module. The gaff rig has been swapped for a square-top main because this boat will probably see a lot of windward sailing and besides, it’s a business expense.

MEA CULPA

Argo is an intriguing concept but there are still many questions. What the actual fiberglass layup will be and what it will weigh is just one among many. How will the molds be constructed? What about the keels? Just how much is this dang thing going to cost anyway? I don’t have the answers to that yet. Let me know what you think in the comments. What about ARGO 3?

THANKS

A great deal of thanks to the Argonauts who have provided their time and insights to the project: Paul Cheevers, John Dalziel, John Pugh and Robert Wise.

———————

Note: ASSOCIATION DES RECHERCHES GLOBALES OCÉANIQUE is not a real NGO, but it should be.

* Yea, that’s an exaggeration, but compared to wood, especially to indifferently maintained wood, it’s true.

** So says sailing legend Paul Johnson.

Congrats Michael. Looks like it is all coming together now. Looking forward to hear what the experts come up with regarding layups.