QB - a 21’ cruising schooner proa

Skip Johnson is building another proa! An avid contributor to the old Proafile forum(RIP), Skip has built some truly radical proas in his day. Toning down the rad half a notch for his latest, QB is a well-proportioned pocket cruiser, using a novel construction method of Gpet sheet foam core and fiberglass. Much thanks for the building report, Skip! -Editor

QB Design and Construction Report

By Skip Johnson

QB aka “Questing Beast” from T H White’s The Once and Future King. Questing Beast is a nigh on perfect name to describe the fool’s errand I’ve traveled for some time now. Unfortunately the phrase doesn’t roll off the tongue smoothly so QB it is. Parenthetically a version of the phrase worked perfectly for my attempt decades ago to build a sub ten pound sit on top, stick and frame with clear winter window shrink film skin. Leastie Beastie was a twelve pound unique marvel until the UV rather quickly destroyed the skin.

QB is a 21’ proa schooner with cambered panel staysails and end mounted rudders. Construction is foam and glass, foam is primarily ½ inch, 5 PCF (pounds per cubic foot) Gpet foam (10 sheets) with one sheet of 12mm Corecell M80 for bottom panels and some scraps of 12mm Corecell M200 bought from fallguy over at Boatdesign.net. Fiberglass is primarily 9 oz tooling cloth with 12 oz biaxial taping and some 22 oz unidirectional tape spot reinforcement. The 9 oz tooling cloth was a mistake; I should have used 12 oz biaxial throughout. The tooling cloth worked fine when vacuum bagged but contact wet out usually required some remediation no matter how careful I was. And the stuff was terrible for shedding where cloth was cut. Virtually all fiberglass work was topped off with a layer of peel ply.

Design weight light is 320 lb which now seems possible, hull weighed 170 lb prior to painting, float is also slightly under the estimated weight but still needs some remediation and fairing.

Other random notes about the boat. Float is based on a Speer P30012 section stretched to about a 7.5% section. Rudders are straight P30012 section. Sliding beams are 3” x 1/8” wall 6061 aluminum tube sliding in HDPE bushings. Masts are sectional step tapered aluminum flagpoles 3” diameter base, 2” diameter cap. Sails are 4 oz Dacron with a leading edge luff of seat belt webbing. Battens are 3/8” c.f. tubing. Auxiliary power is an A.D. style scull with fiberglass blade and aluminum tubing shaft. A number of bits; navigation lights, ball and socket set for scull and ratchet mechanisms for roll up sail reefing are 3D printed pieces.

The Construction Process

See photos above

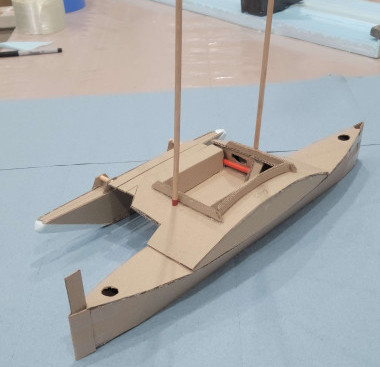

- A 1:12 size model in corrugated cardboard. Illustration board, the old gold standard isn’t readily available here in the hills of Oklahoma.

- Surprisingly the model weighed in matching the design displacement. The mannequin however was seriously underweight hence the bolt style pfd. Not really visible in the photo is a chunk of XPS foam on the lee side of hull with the same scale volume as a 9” diameter 60” long inflatable beach roller/fender.

- Layout table under construction. Three H.C. door panels 36"x 80” with a supporting lightweight framework. Table weighs around 100 lb and is easy to set at different heights depending on needs of an old man that tries to avoid much bending over.

- Assembly. Hull sides are 24” wide panels 20’ long. Bottom plank is a parabolic curve with an exponent of 5. Sheer is a more rational 3. The prismatic coefficient is 0.76. The split piece of lightweight pvc pipe was trough to wet out ½” unidirectional tape along gunnels held in place by wood strip covered with packing tape.

- Bulkheads, berth flats and ring frames installed. Trammeling from several different points hull seems to be symmetrical within an 1/8” or so.

- Hull has been flipped over and the bottom glassed, lapped over the bottom to just over the waterline for an 18 oz bottom. While still upside down the bottom was coated with a thick graphite/epoxy bottom coat.

- Assembly continues. Hull now in a cradle with rollers so boat can be moved around a bit. The 2x4 frame on leeward side makes it easy to tilt the boat over for easier access to inside and the underside of seating pod.

- Shunting day. Until now it’s been advantageous to work with weather pod towards the right side of shop. Eventually the boat will need to go on the trailer with weather pod to the other side (passenger’s side of vehicle). Power boat has been pulled out and move was easy on roller equipped cradle.

- Back in the shop.

- Boat is now off the rollered cradle and sitting on 2 2x4’s at about where the sliding beams will be, boat rolled over on side for better access to interior and underside of seating pod.

- Interior is painted Gripper primer and polyurethane porch enamel. Horizontal surfaces get an extra coat with non slip additive.

- Current state, deck with a coat of primer.

Looks good, Skip. I like the cockpit/deck to windward. Lots of places

to sit. Looking forward to seeing it sailing.