The Camel: a sailing cargo proa

The Camel of the Sea is a sailing multihull cargo vessel designed for operation by a small crew of 3-6 in areas of steady winds and expensive petroleum. As outlined in The Case for the Cargo Proa, physics favors the proa configuration in the case of widely varying displacement. In this example, the fully laden boat weighs over three times the boat when empty. To recap the argument:

Widely variable displacement on multihulls is a significant problem, because displacement x righting arm = righting moment, and righting moment governs everything else in the design of a sailing vessel. The long righting arm of the multihull multiplies displacement into a formidable beast.

It is prudent to design for worst case, or the most laden condition. A heavily laden multihull has an enormous righting moment, leading to bigger sails, greater stresses, larger and stronger structural members, adding even more weight, and up the design spiral we go. The vessel quickly becomes expensive to build, maintain and to operate, cutting into profit and the reason for building the boat in the first place. Conversely, when the multihull is lightly laden it is needlessly overbuilt and over-canvased.

The only way around this conundrum is with the proa, which does not require bilateral symmetry.

On a proa, cargo may be loaded entirely into the leeward hull, which is also the center of buoyancy. There will be very little change in righting moment no matter how heavily laden the proa might be. With a proa, righting moment is handled by the weighted ama and outrigger structure to windward, not buoyancy to leeward. The righting moment remains consistent, meaning stress, scantlings and sail area will also remain consistent between laden and unladen. This leads to a well-engineered and efficient structure through a widely varying displacement.

Conceptually, the proa decouples the driving force from the overall displacement. Sailing loads do not skyrocket as cargo is loaded. The ship should sail and handle much the same whether laden or unladen, the only difference being speed attained.

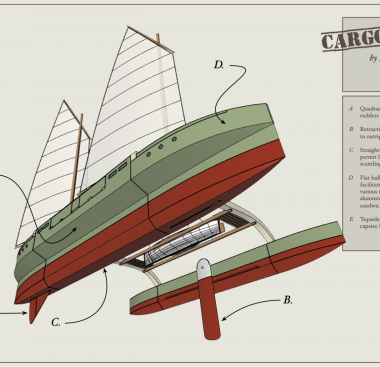

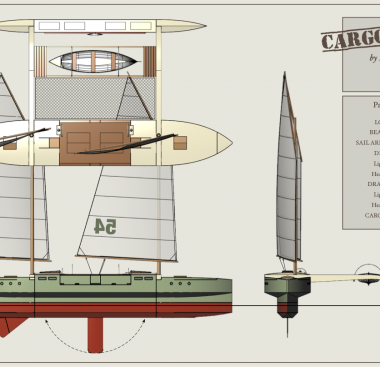

General Specifications

The Camel is 54’ LOA with a 29’ beam. Waterline beam is 4’ which provides a slender 13.5/1 L/B ratio. However, the hull flares above the waterline out to 9’, providing buoyancy to leeward and extra righting moment in the event of a knockdown. The “counterpoise” is a feature of traditional Micronesian canoes that provides safety against capsize and additional deck space. The broad back of this camel also provides much needed interior volume for accommodations and cargo, as well as comfortable working decks.

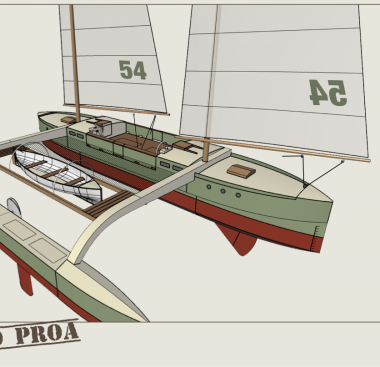

Sail area is 886 sq. ft. split between two standing lugs. The masts are free-standing. The lugs have the advantage of balancing the sail area forward of the mast, reducing sheet loads. This is a benefit for a vessel that must shunt to change direction, and reverse the rig for every tack. I make no claims that The Camel will be a delight to sail, and will more than likely take after her hard-mouthed namesake when coming about. However, being a working vessel, if the economics pan out, then the captains of cargo proas may consider the handling trade-off to be well worth it.

A headsail may be rigged if not too large (headsail luff sag is a challenge for unstayed masts). However, given that shunting requires two of them - fore and aft, and that the aft headstay (you gotta love twisting nautical terms past their breaking point on proas) interferes with the aft boom so that it can no longer swing out to the ama side, thus removing the option to sail “wing on wing”, it would be at the captain’s discretion.

All underwater surfaces retract in the case of hitting a submerged obstruction or grounding, and for beaching. Draft is 1’-3” light, 3’-3” fully laden. The rudders are quadrant-style that retract into cases like centerboards. Only the aft rudder is employed, which also shifts the CLR aft to balance out the aft position of the schooner rig’s CE. The pivoting leeboard on the ama is actually to windward of the hull, so call it what you will. The board is adjustable to fine-tune the CLR as well.

Righting moment is provided by stores and water ballast in the outrigger or ‘ama’.

With a proa’s shunting requirement, auxiliary power is problematic at best. I don’t have a perfect solution, though I admire the Harry Proa idea of a custom outboard launch used as such. Some kind of retractable electric drive would be ideal, powered by a generator and/or solar cells, but I suspect we are letting our budget get out of hand with that one. For now I am simply penciling in space below the cabin sole labeled “auxiliary power - TBD”.

Accommodations

The hold is situated directly amidships - 14’ long and 6.5’ deep. Max cargo is 12 short tons. Two large deck hatches open to provide loading access. The sail booms are rigged as cranes to load cargo from either a dock, small boats alongside or directly from shore. the lee side bulwark may be rigged as a gangway.

Accommodations are situated fore and aft of the hold. One end contains the head (though it is situated in the stern half of the time), a two bunk cabin, and a pilot’s cabin with nav area and a berth. The other end contains the galley and crew’s mess - settees double as another pair of bunks.

The boat is helmed and sailed from the central cockpit above the hold. The 126 sq. ft. deck will also provide a comfortable lounge space when under a boom tent.

I’ve drawn in a romantic 18’ sailing/rowing launch for the tender, even though an outboard-powered rigid inflatable is more likely. It docks safely above the water’s surface between the beams, and is easily deployed via overhead block and tackle. The 24’ between the beams can provide plenty of stowage for multiple tenders, paddle boards or what have you.

Hull Shape and Construction

All hull surfaces are “developable”, meaning the boat can be built of flat sheet material like plywood, aluminum or KISS®-style foam composite panels. Materials will be specified as necessary by local availability. Taking a page from Phil Bolger’s playbook, sections are as square as possible: vertical hull sides with no flare, a dead flat sheer and chine, and a flat bottom. The hull is a 5-panel design to provide a smoother ride and reduced wetted surface - compared to a true sharpie-style flat bottom.

The ama has a sharp V-shape bottom to provide a well-modulated ride at varying angles of heel, immersion and wave states. The ama deck is also V’d to shed water when immersed.

One design aspect borrowed from ships and jets is a constant mid-section between the beams. This permits the build to be easily modified to suit. The mid-section may be lengthened or shortened depending upon requirements with no changes required to beams, masts, foils, etc. The constant section also speeds up construction of internal furniture or fittings.

Even though The Camel is a working vessel, when lightly laden the boat would still be capable of showing the speed that made proas famous. This will make for fast return passages, as well as spirited racing.

Please note: The design is a sketch concept only. No plans exist.

Hi Michael,

I always enjoy perusing your talented concepts. You never fail to deliver fresh, doable, out-of-the-box ideas and this project is no exception.

The respectful nod to brother Phil (R.I.P.) was also well appreciated.

“Cargo Proa” has that “I didn’t come here to dance” look about him. All straight forward function and solid business. Both from the building point of view and his endgame usage. It would be hard to put together a more functional pile of plywood and epoxy than CP. And that retro/futuristic look…You nailed it!

Cheers from the Yucatán,

Claudio